.JPG)

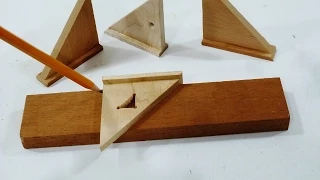

Bending wood can be done easily using this Kerf Jig. This jig will

allow you to cut evenly spaced kerfs very quickly on plywood or

any other stock.

I made this Wooden Miter Gauge for Table Saw a while back and

it works great, in fact I use it all the time. With the large back and

sandpaper it is easy to hold and secure many different sizes

of wood.

A small addition for the Miter gauge.

This will be a block with a pin that can be easily attatched to the miter

gauge to make a new jig for cutting kerfs.

it works great, in fact I use it all the time. With the large back and

sandpaper it is easy to hold and secure many different sizes

of wood.

A small addition for the Miter gauge.

This will be a block with a pin that can be easily attatched to the miter

gauge to make a new jig for cutting kerfs.

The first thing to do is make a pin so I thought I would use an Allen

key. I have collected many keys over the years and thought I could

find the right size. The key size you need should be the same thickness

of your table saw blade, usually 1/8th inch.

I found one but had to grind/sand it down a bit to get the 1/8".

You can use a belt sander to get the right thickness.

I found some wood in my scrap pile to make a stop block. Maple

is best but any hard wood should be fine. Rip some pieces to

3/4x1x3 1/4" and the top piece, 3/4x1/2x3 1/4". The top piece

has a dado the thickness of the miter gauge back. Drill a hole in

the center of the block . Make sure the hole is smaller than the

Allen key for a tight fit.

together. Keep everything square and test on the miter gauge back.

.JPG)

A small notch is chisled out, this is for the Allen key so it will

sit flush on the bottom of the guide block.

.JPG)

The key is tapped in with a hammer and everything is square

and flush. I did not glue it because the Allen key fit very tight.

If you have too you can use some CA glue.

.JPG)

A cut is made for the pin 1/4" away from the blade. This is done

by raising the miter gauge off the table using some scraps the

thickness of the runner and moving the miter gauge over the blade.

The depth of the cut should be the height of a Allen key, mine

turned out to be 4mm.

.JPG)

The guide block is simply snapped on.

......One small modification.

A second cut is made on the other side of the blade. Now the

guide can go on either side of the blade making it easy to make

cuts on both sides of the stock.

A close up of the pin, blade and the other slot.

Remember to use a Zero-clearance insert for the saw

to prevent chip-out.

This is my first try, it went very fast and the spacing was perfect.

I did not set the blade high enough so the board did not bend that

easily. I tried a second piece and it was cheap Chinese wood and

it crumbled as I was bending it. I caught this on video and it made

me laugh.

.JPG)

This is my third attempt, a better piece of plywood and it turned

out great. It bent fine but I used some steam from a kettle to ensure

there would be no cracking.

I hope you enjoyed this and get some value from my posts. If

you want to build yours and have any questions about the build

please ask!

Any ideas what I should make out of bent wood let me know,

or show me what you have made. Please comment.

This should be fun!

See also:

Make a Multi Blast Gate Make a Mini Speed Square

Make a Screwdriver Center Line Finder

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)