Can Paper cut metal? After watching John Heisz's video "Can Paper Cut Wood" I was intrigued and thought about what else it can cut. I wanted to try something different so I came up with this idea of cutting metal with playing cards and using a router.

The router spins up to 30,000 RPM which is necessary for a paper blade to cut metal. It needs to spin fast to work. As for the metal, I will be using an aluminum can, it is a soft and malleable metal.

Make a paper saw blade

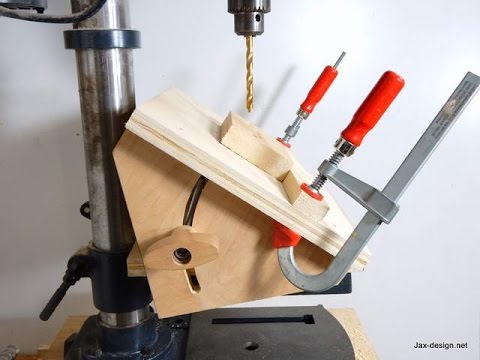

The first part to make would be the 1/4" shank. A piece of threaded rod works best for this.

Quick tip; Bolt cutters are used to cut a piece of threaded rod to the desired length. It cuts easy and you don't have to pull out the hacksaw.

I used my new Belt Sander and took off the rough edges of the threaded rod. This will look better and make it safer to handle... and makes it easier to put the nuts on.

For the saw blades I will be using playing cards. I used a compass the type with two points and cut out a couple of blades. Several blades will be made since they will wear out quickly.

To enlarge the hole for the 1/4" shaft I used a punch, this is the same size as the threaded rod that will be used.

The router setup. A Makita compact router and table will be used. This is a very handy table for small jobs.

The paper blade is put on the threaded rod or shaft and tightened with a couple nuts and washers. Two wrenches are used to make sure the nuts are tight, then it is placed in the router collet and tightened. Keeping the blade low to the table seemed safer to me.

This was the first cut, it was very clean and cut fast up to a point then the blade would wear quick and start to wander.

It took three blades to cut the can. The blades are easy to make and exchange.

Making saw blades from paper is very interesting, and to find out if they cut metal was incredible. This was more of a test to see if it would work. I probably would not make any more but I always like to experiment.

If you want to make your own paper blades this is very easy. Let me know if you do.

What else do you think paper would cut?

You may also like:

Marble Spring Gun Diamond plate toolbox Wood Clipboard