I came up with this idea for a new tool, I call it a tool ring. A wooden ring with rare earth magnets. This ring fits comforabley on your finger and can be used to hold small tools, hardware and also for picking up small parts.

I used my magnet sepaerater to get a 3/4" rare earth magnet.

To start I found a small piece of hardwood, I made sure one side was square and scribed some lines using my mini speed square .

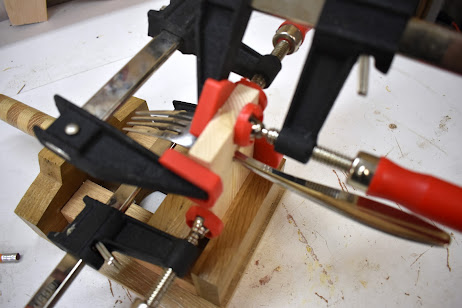

I drew the rough shape of the rings and cut the rough shape on the bandsaw. The rest of the shaping was done on the beltsander with 80 grit paper and the fine sanded by hand using 220 grit..

Here one is rough and one is sanded. Very easy once it it shaped on the beltsander with a good eye and fine sandpaper.

I used some gorilla glue for the magnets, after they are dry I used some fine

sandpaper to clean any glue residue.

Here I put on a few screws and a drill bit. Not only does it hold well it also held up when I was working on a project.

Here is a video showing how I made it:

.JPG)

.JPG)