%2B(640x443).jpg)

My oscillating spindle sander is complete. It fits on the drill press

table and a vacuum can be hooked up easily to the side. The last three videos I made are related to the build.

.jpg)

To make the table I started with some 3/4" Baltic birch for the top and bottom and cut 2 pieces to 9"x 13". Since I was building a type of box I thought it would be a good idea to make a door so I could store the spindle sanders, this door would also be used for the vacuum.

.jpg)

.jpg)

A 2/14" inch hole saw is used to drill the hole for the vacuum. This is attached to the box with one hinge. The height of the door is slightly smaller in the frame for clearance. The top and bottom can now be secured to the box.

A hole is drilled in the top slightly lager than the spindle. This is repeated on the other side with a smaller hole for the smaller size spindles. This is done so I didn't have to mess around with throat plates.

The spindle sanders are stored in the box.........

.jpg)

Here are both the large and small spindle sanders in use, just flip the table, clamp and ready to be used. This can be done with the vacuum hose left in.

I hope you enjoyed this build, don't forget to comment!

See also:

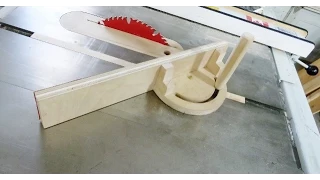

Making spindle sanders Dowel stop gauge Make a miter gauge

.jpg)

.jpg)

.jpg)

.jpg)

Wow, really nice to see the finished product! You must feel proud after accomplishing your own spindle sanding table - I don't think I'd be able to do something like this in my life.

ReplyDeleteThanks James, you can do it, study a little bit everyday and take your time.

ReplyDeleteOh, I don't know. I actually tried getting started with it a couple of weeks ago. I have made some progress but it takes A LOT of patience and dedication.

ReplyDeleteAfter a long time, I came across a good post on sanding table again. I really owe you thanks, dear Jack Houweling! I believe you can help more by expanding the topic further. At least, I can benefit from it greatly, and so can the regular readers of the sweet spot- Sandersreview.

ReplyDeleteLike to see your finished oscillating spindle sander. I know that it takes a lot of patience.

ReplyDeleteThis blog post provides an informative and comprehensive overview of the oscillating spindle sanding table. It clearly explains the design, construction, and use of the tool, as well as the advantages of using it. vpn software The photos and diagrams are very helpful in illustrating the various features and benefits of the product. This is a great resource for anyone who is looking to learn more about this type of tool.

ReplyDelete0486B17A30

ReplyDeletekiralık hacker

hacker kiralama

tütün dünyası

-

-